News & Events

27 mai 2021

Status overview of the LEMON instrument manufacturing

This news article aims to provide an update on the work performed within the key project work package focusing on the manufacturing of the DIAL LIDAR instrument, under Fraunhofer ILT leadership.

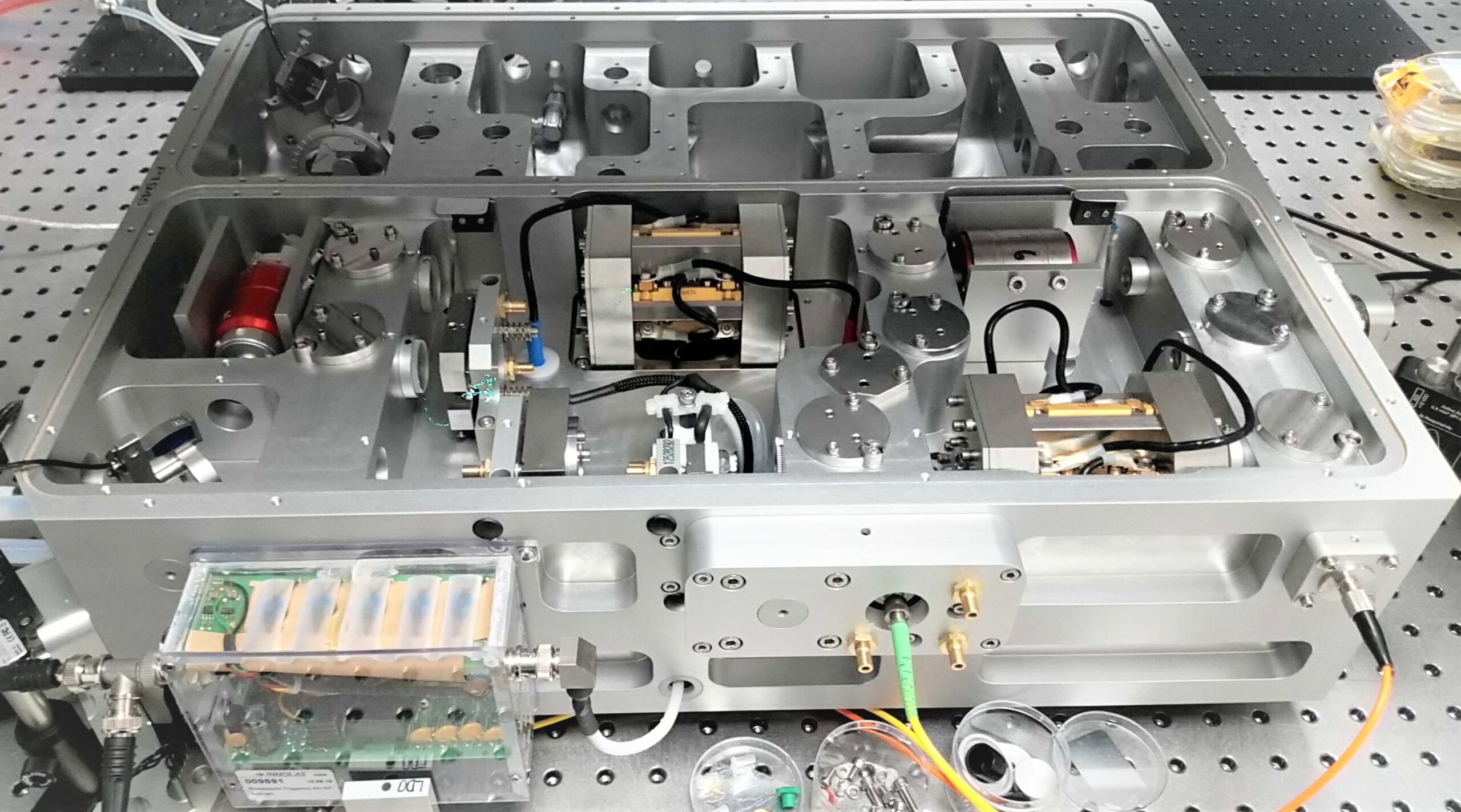

After the successful Optical and Mechanical Readiness Report as an output of the design phase, the LEMON project entered the next stage with the start of the manufacturing of the various subsystems. The main subsystems that define the performance of the DIAL system are the transmitter TREE, the receiver ARM and the frequency reference unit FRUit. The mechanical designs and especially the interfaces ensure a stable beam delivery between the subsystems, even for the challenging environment during the measurement flights.

The emitter design consists of (1) a pump laser emitting at 1 µm and supplying the energy for the OPO that generates the targeted wavelength; and (2) the OPA that amplifies the targeted wavelength to high pulse energies.

As of end of April 2021, the pump laser is equipped with all electronics, and the optical design process is now nearing completion. The pump laser, built by InnoLas, includes the folded and seeded laser oscillator, the amplifier, the space for two separate OPOs that will be integrated by ONERA and all necessary beam shaping and its stabilization by two piezo mirrors.

In the main beam after the isolator, the MOPA system delivers a pulse energy of >250 mJ at a center wavelength of 1064 nm with a Gaussian beam profile, a beam quality factor of M2 = 1.4 and a pulse duration of 10 ns. During the measurement campaign, the laser has to be operated in double pulse mode with online and offline wavelength, meaning that pairs of pulses with a delay of 500 µs are emitted at a global repetition rate of 75 Hz instead of single pulses at a repetition rate of 150 Hz. The pulse-to-pulse energy stability was measured to be <0.2 % (RMS) and the polarization purity to be better than 93 %. All requirements are so fulfilled and the laser will be delivered to ONERA, where the OPOs will be included.

The OPO consists of a temperature-controlled nonlinear crystal with two entangled cavities built with two mirrors, which positions are controlled with lownoise piezoelectric transducers. It is built around an ultra-low expansion glass (zerodur) frame to minimize the cavity displacements and misalignment due to temperature gradients. The alignment of the crystal and cavity mirrors is realized with external tools that are used to tighten the mounts on the frame, while enabling some translation in the vertical planes defined by the zerodur main frame. The first OPO is currently set up, aligned and characterized in an optical test stand before it is integrated into the pump laser housing .

The housing for the OPA and all components were fabricated and are currently preassembled and tested under changing environments. Afterwards, the emitter subsystems will be set up on a common carbon bench that is currently being manufactured. Also, the central subcomponents of the FRUit are currently being built and will be integrated in the hermetically sealed mechanical housing. Meanwhile, the manufacturing and assembly of the overall instrument with the receiver and the structure mechanics made of carbon tubes and aluminum plates is ongoing.

In parallel, discussions are ongoing with Safire about the integration of the instrument into the ATR 42 airplane.

Picture on the right: the LEMON pump laser, built by consortium partner InnoLas.

![Video of first DIAL ground-based validation campaign [French]](https://lemon-dial-project.eu/wp-content/uploads/2021/11/lemon-250x101.png)